SM3-39

2:1 Continuous Printable Polyolefin Copolymer

USP Class VI

Applications

- Medical device identification

- Withstands radiation and gas sterilization methods.

- Compatible with gamma and e-beam irradiation and gas sterilization processes.

- Contains less than 1 ppm of heavy metals.

Product Overview

Category

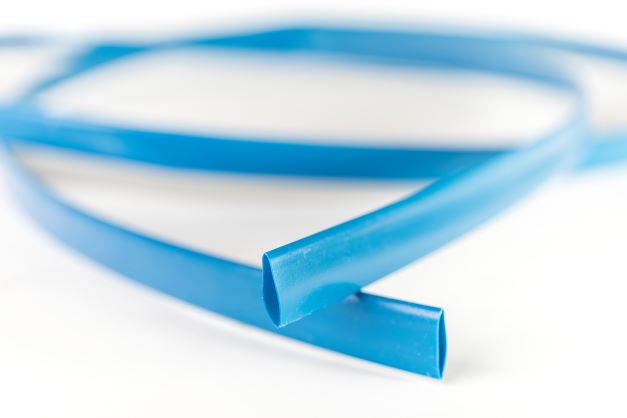

Heat-shrinkable tubing

Material

Polyolefin Copolymer

Shrink ratio

2:1

Shrink temperature

115° C

Continuous operating temperature

-55° C to +105° C

Available colors

Blue

Flammability

Non Flame Retarded

Environmental compliance

Specifications / Approvals

Other

Additional Information

Design

Continuous

Mark Performance

SAE-AS5942

Fluid Resistance

-

Recommended Printer

-

Recommended Ribbon

SM3 White Ribbon

Software

Sumilabel

Basic Properties

| Property | Test Method | Requirement |

| Physical: | ||

| Tensile Strength | ASTM D 638 | 1500 min. |

| Elongation (%) | ASTM D 638 | 200 min. |

| Specific Gravity | ASTM D 792 | 1.0 max |

| Low Temperature Flex (-55° C) | AMS-DTL-23053E | No cracking |

| Heat resistance (136° C, 168 hrs.) | ||

| Elongation (%) | ASTM D 638 | 100 min. |

| Longitudinal change (%) | AMS-DTL-23053E | +5, -15 |

| Secant Modulus (psi) | ASTM D 882 | 2500 max |

| Electrical: | ||

| Dielectric strength (volts/mil) | ASTM D 876 | 500 min. |

| Volume resistivity (ohm-cm) | ASTM D 876 | 1.0 X 1015 min. |

| Chemical: | ||

| Heavy metals content | <1 ppm | |

| Water absorption | ASTM D 570 | 0.2 max. |

*For reference use only

Sizes

| Nominal Size | ID Minimum (As Supplied) | ID Maximum (After Recovery) | Wall Thickness Nom (After Recovery) | |||

| Inches | MM | Inches | MM | Inches | MM | |

| 1/16″ | .063 | 1.6 | .031 | 0.8 | .017 | 0.43 |

| 3/32″ | .093 | 2.4 | .046 | 1.2 | .020 | 0.51 |

| 1/8″ | .125 | 3.2 | .062 | 1.6 | .020 | 0.80 |

| 3/16″ | .187 | 4.8 | .093 | 2.4 | .020 | 0.90 |

| 1/4″ | .250 | 6.4 | .125 | 3.2 | .025 | 0.90 |

| 3/8″ | .375 | 9.5 | .187 | 4.8 | .025 | 0.90 |

| 1/2″ | .500 | 12.7 | .250 | 6.4 | .025 | 0.90 |

HOW CAN WE HELP?

For any information please Contact Us