SM3-23

3:1 Continuous Printable Overexpanded Polyolefin

AS23053/5 Class 1

UL/CSA recognized 125° C 600 V (VW-1)

Product Overview

Category

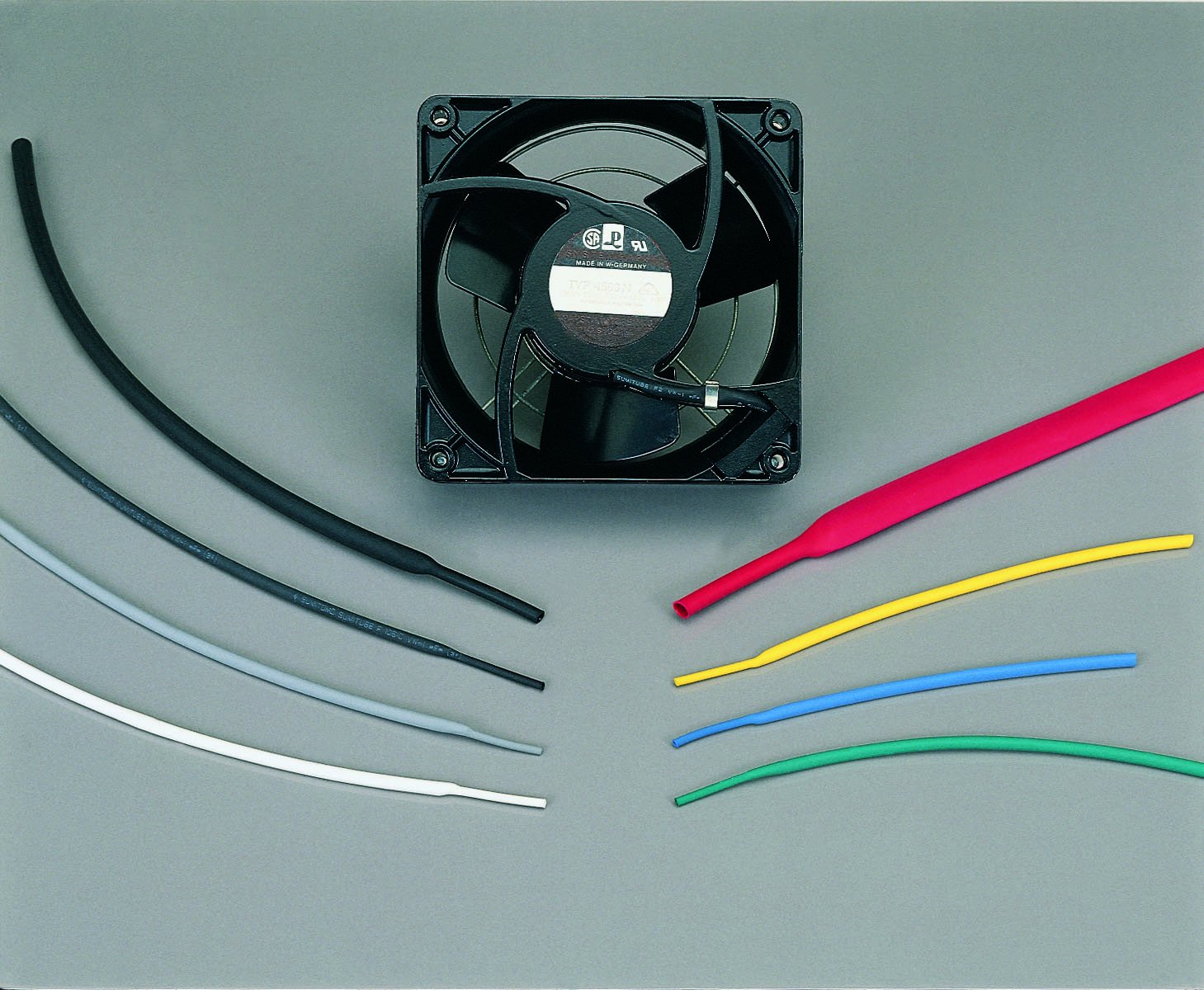

Heat-shrinkable tubing

Material

Overexpanded Polyolefin

Shrink ratio

3:1

Shrink temperature

90° C

Continuous operating temperature

-55° C to +135° C

Available colors

Black, Yellow, White

Flammability

Flame Retarded

Environmental compliance

RoHS/RoHS2

Specifications / Approvals

Other

Additional Information

Design

Continuous

Mark Performance

SAE-AS5942

Fluid Resistance

-

Recommended Printer

-

Recommended Ribbon

SM3 Black Standard

Software

Sumilabel

Basic Properties

| Property | Test Method | Requirement |

| Physical: | ||

| Tensile Strength | ASTM D 638 | 1500 min. |

| Elongation (%) | ASTM D 638 | 200 min. |

| Specific Gravity | ASTM D 792 | 1.35 max |

| Low Temperature Flex (-55° C) | AMS-DTL-23053 | No cracking |

| Heat shock (250° C, 4 hrs.) | AMS-DTL-23053 | No cracking |

| Heat resistance (175° C, 168 hrs.) | ||

| Elongation (%) | ASTM D 638 | 100 min. |

| Longitudinal change (%) | AMS-DTL-23053 | +5, -15 |

| Secant Modulus (psi) | ASTM D 882 | 2.5 X 104 max |

| Electrical: | ||

| Dielectric strength (volts/mil) | ASTM D 876 | 500 min. |

| Volume resistivity (ohm-cm) | ASTM D 876 | 1.0 X 1014 min. |

| Chemical: | ||

| Corrosion (175° C, 16 hrs.) | UL 224 | no corrosion |

| Water absorption (%) | ASTM D 570 | 0.5 max. |

| Fluid resistance (23° C, 24 hrs.) | ||

| Tensile strength (psi) | AMS-DTL-23053 | 1000 min. |

| Flammability | UL 224 | Pass |

| Shrink temperature, nominal | 90° C |

*For reference use only

Sizes

| Nominal Size | ID Minimum (As Supplied) | ID Maximum (After Recovery) | Wall Thickness Nom (After Recovery) | |||

| Inches | MM | Inches | MM | Inches | MM | |

| 1/16″ | .063 | 1.6 | .021 | 0.5 | .020 | 0.5 |

| 1/8″ | .125 | 3.2 | .062 | 1.6 | .020 | 0.51 |

| 3/16″ | .187 | 4.8 | .093 | 2.4 | .020 | 0.51 |

| 1/4″ | .250 | 6.4 | .125 | 3.2 | .025 | 0.64 |

| 3/8″ | .375 | 9.5 | .187 | 4.8 | .025 | 0.64 |

| 1/2″ | .500 | 12.7 | .250 | 6.4 | .025 | 0.64 |

| 3/4″ | .750 | 19.1 | .375 | 9.5 | .030 | 0.76 |

| 3/4″ | .750 | 19.1 | .375 | 9.5 | .030 | 0.76 |

| 1″ | 1.00 | 25.4 | .500 | 12.7 | .035 | 0.89 |

HOW CAN WE HELP?

For any information please Contact Us